The kiln can make the brick dry evenly and quickly in a wide drying period (depending on the uniformity of the whole process parameters and the stability of the brick conditions). The kiln is composed of roller table box, each section of kiln body is distributed with roller bar, which forms three consecutive transport channels.

Main technical parameters of drying kiln:

Length: 109.2m

Standard unit section number (2.1m): 52 sections

Rated width of channel: 2.3m

Drying temperature: < 250 ℃

Water content of billet in kiln: ~ 18%

Water content of billet outlet: About 0.5-1.0%

B. kiln for burning roller

(1) Technical parameters

Length: 203.7m, standard unit number (2100mm): 97 sections

Among them, drying in front of kiln: 8 sections, burning kiln: 89 sections

Rated width of firing channel: 2300mm, effective firing width: 1900 mm

Maximum loading height: < 50 mm: ≤ 50mm

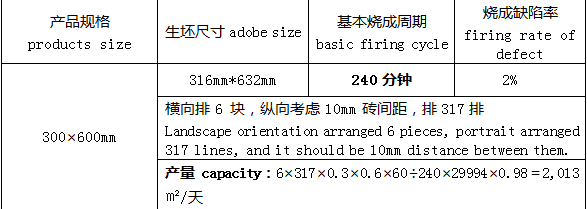

(2) Basis of production calculation

Brick is the basic product, and the output is shown in the table:

Note: the final firing time depends on the formula, the thickness of the green body, the moisture before entering the kiln and other factors. The basic period of 240 minutes is only a slightly conservative theoretical reference time for calculating the output.